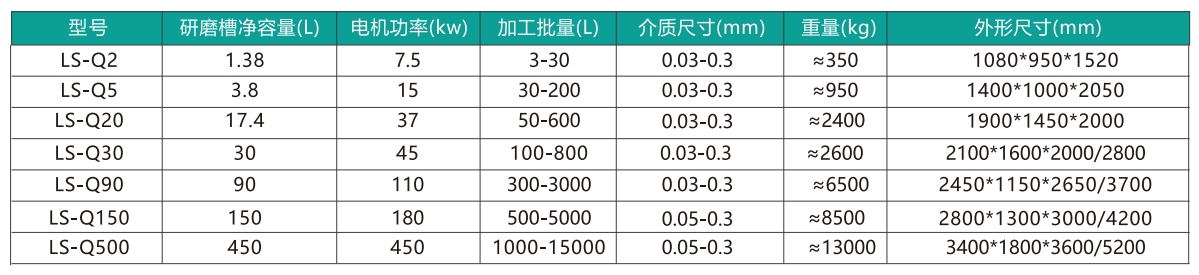

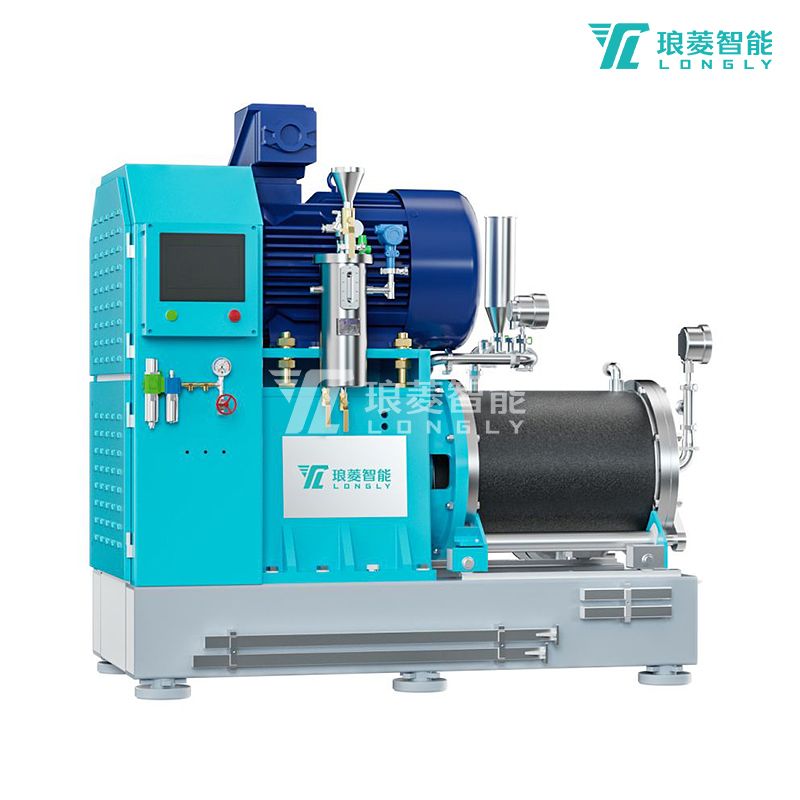

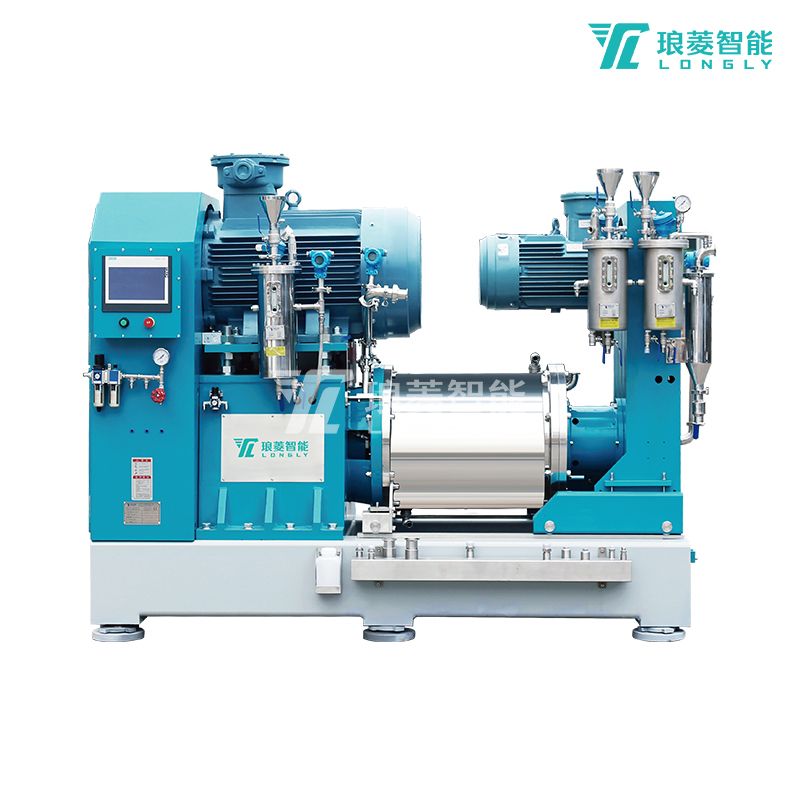

Single power vertical nano sand grinder LS-Q series

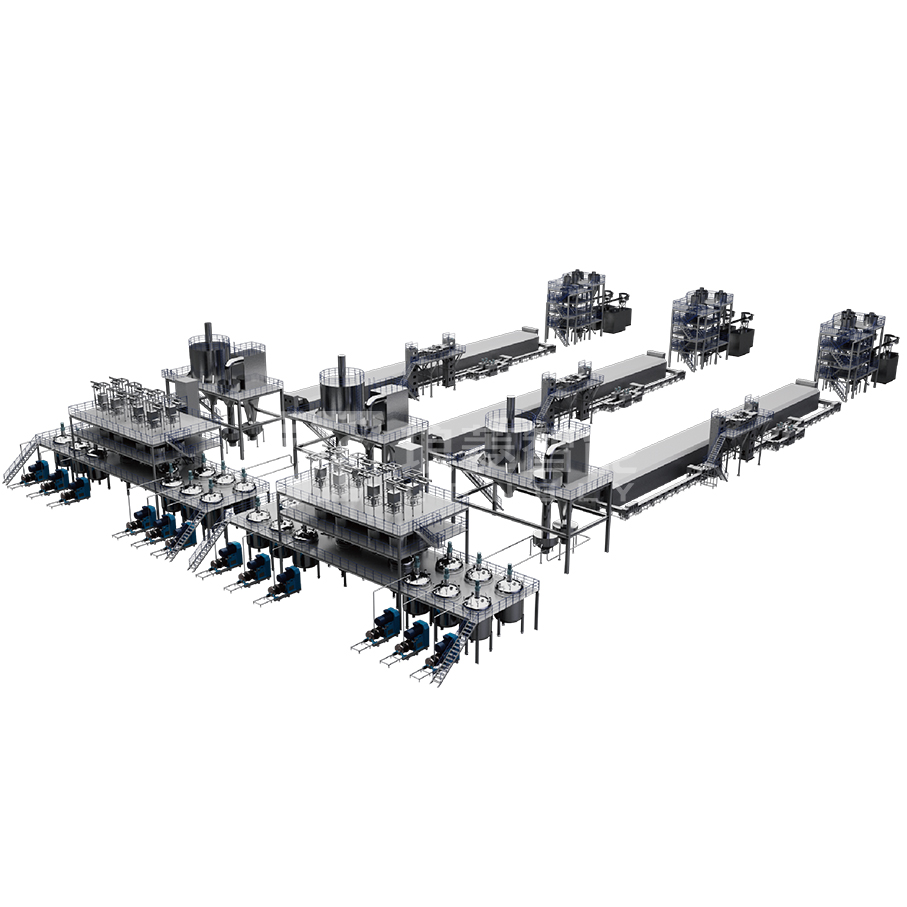

LS-Q series,the single-powered vertical nano bead mill is an important nano-scale grinding equipment. The output fineness is 80-300nm, and the Zirconia Bead Size is optional from 0.03 to 0.3mm. The centrifugal separation method is adopted, and the grinding structures are usually a new type of the turbo disk and the pin. The net capacity of the grinding chamber can be selected from 1.38L-145L. At present, there are four models, LS-Q2, LS-Q5, LS-Q20, and LS-Q150, and the processing batch can reach up to 3000L.

◎ Grinding particle size: 80-300nm

Zirconium ball size: 0.03-0.3mm

◎ Separation system: centrifugal separation

◎ Grinding structure: New vortex disk/rod pin type

Application industry:

◎ Lithium iron phosphate ◎ Electronic ceramics ◎ Zirconia/silicon oxide ◎ Barium titanate ◎ Nano new materials ◎ MLCC ◎ High end capacitors

Home

Home