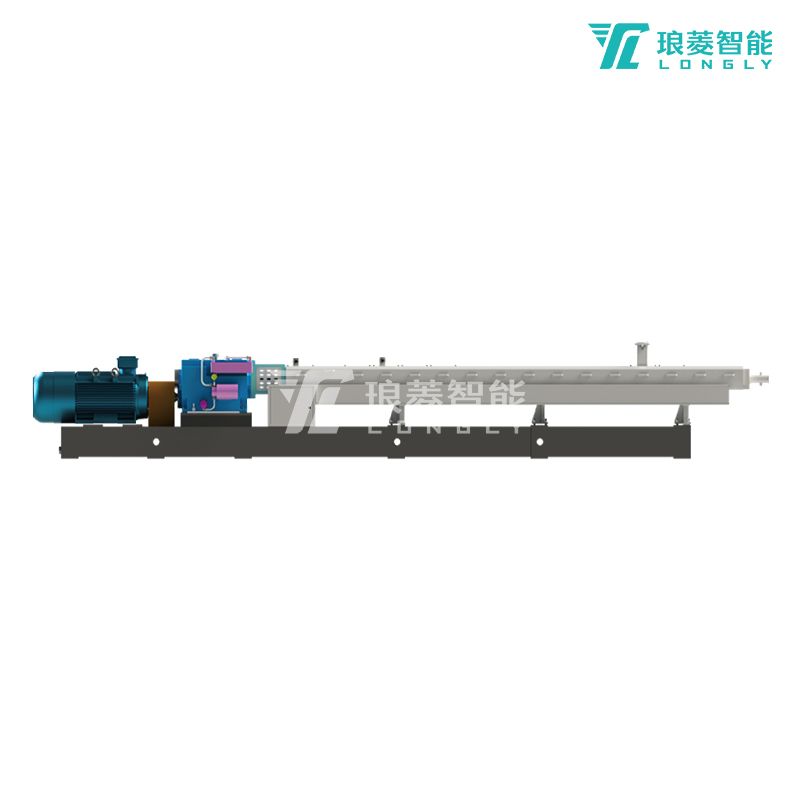

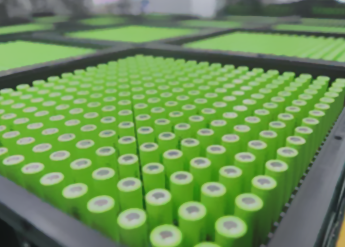

The product developed by Langling intelligent for the lithium battery industry is a new type of pulping process using twin-screw continuous pulping.

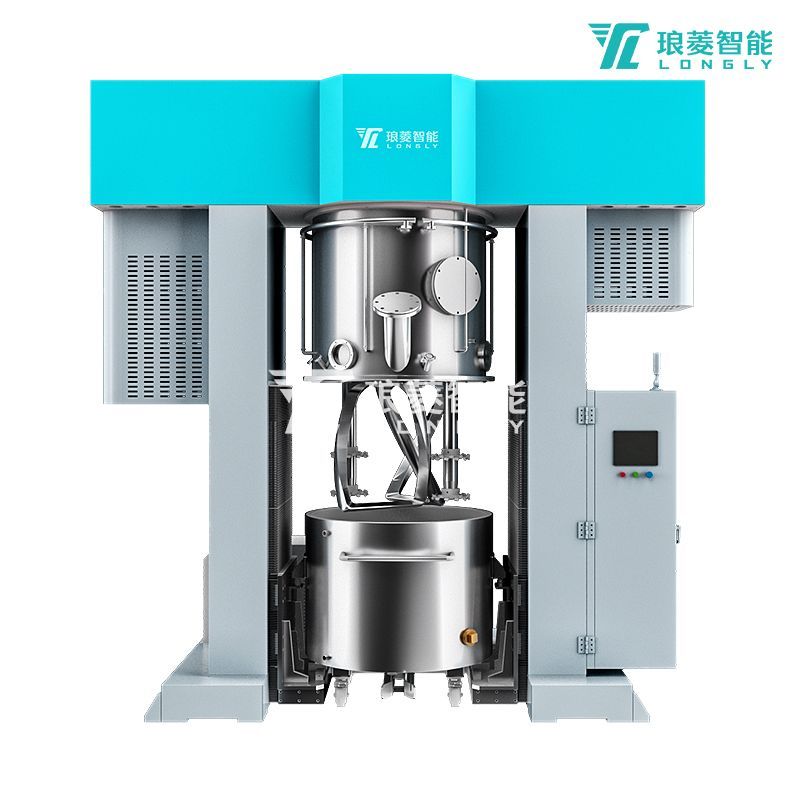

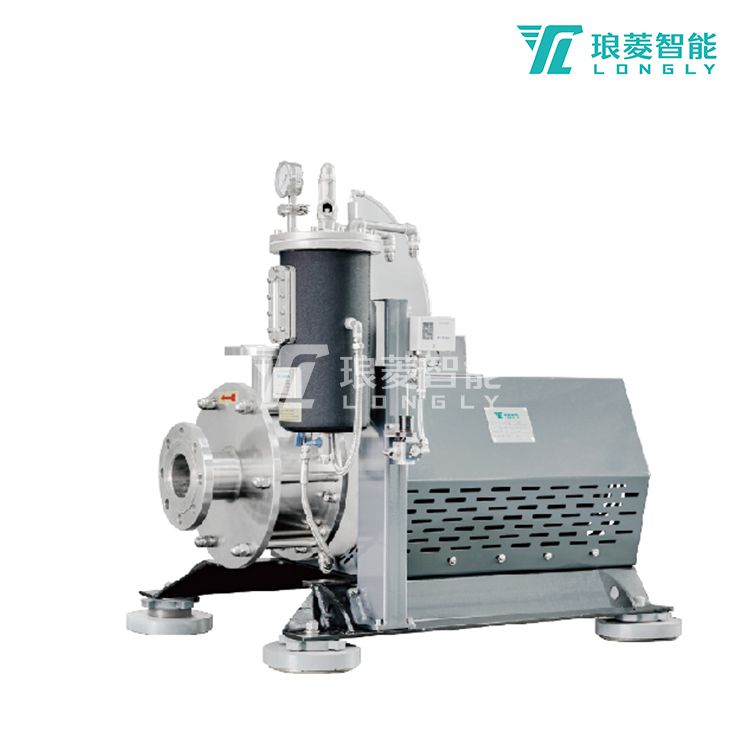

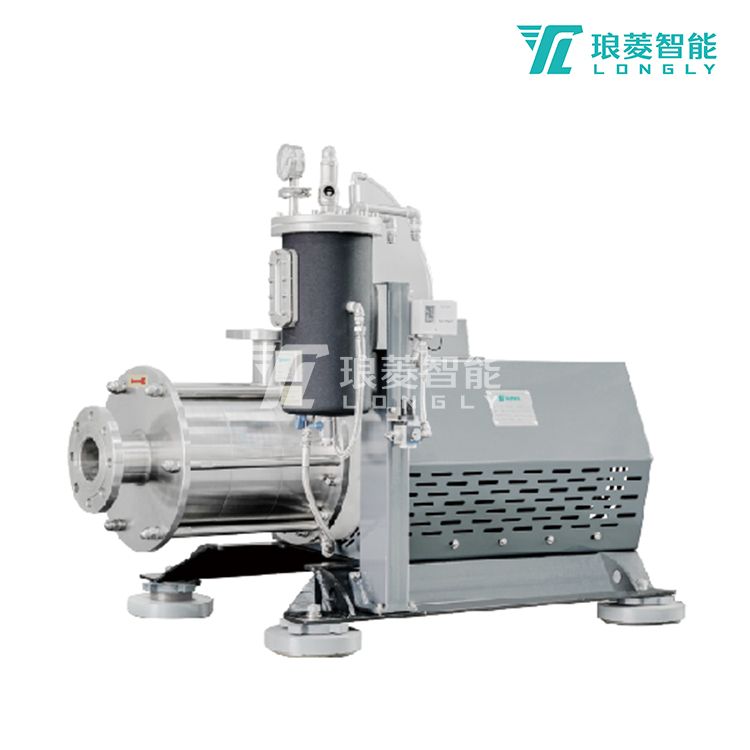

◎ Double screw continuous pulping machine, modular double screw structure, integrated conveying, mixing, dispersion, exhaust in one, can realize continuous material processing, continuous discharge, function to achieve free collocation, to meet the needs of different working conditions; Solve the cost and energy loss caused by single function.

◎ Continuous homogenization process is derived from the twin screw extruder, which is to add different raw materials to the premixed twin screw extruder according to different ratios by the weightless feeder, premixed the powder, and then add the premixed powder to the twin screw host, and then mix with different liquid raw materials according to different ratios, mix, mesh, shear, disperse in the long and narrow barrel of the twin screw. Negative pressure drawing, extraction and exhaust, so that the material in the mixing process received diversification and dispersion, and finally achieve better mixing effect.

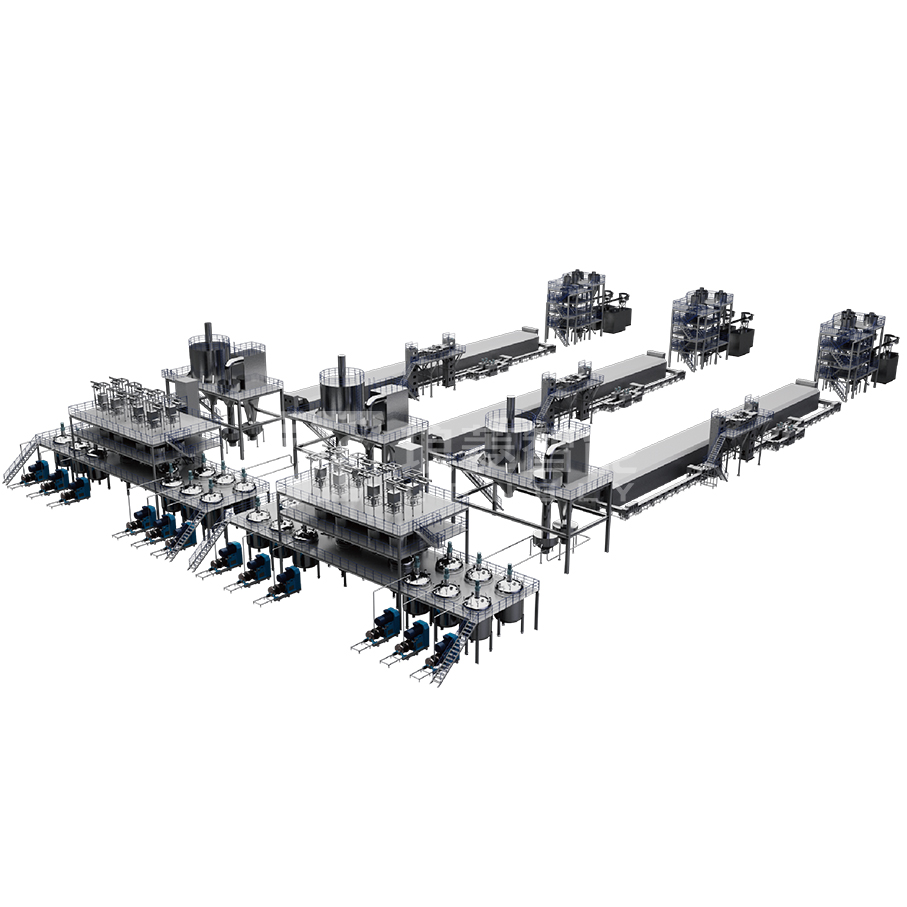

Langling intelligent to provide homogenate line solution. It realizes automatic metering, precise dosing, stirring dispersion and efficient transportation of powder, solution and slurry. Our technical experts according to the viscosity of the product, characteristics and other parameters for customers with the appropriate selection, but also according to your various processes, there are different forms of equipment to match and optimize the combination, so that the system to achieve the best state.

Application Industry:

◎ Lithium battery material ◎ Diaphragm ◎ Electronic ceramics ◎ nanomaterials ◎ 5G material

Home

Home