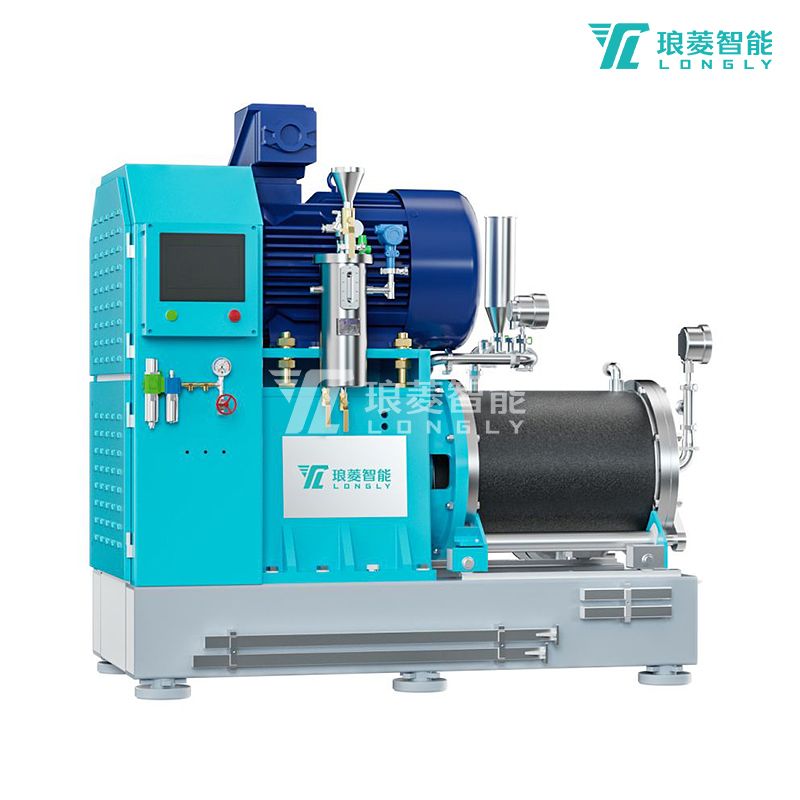

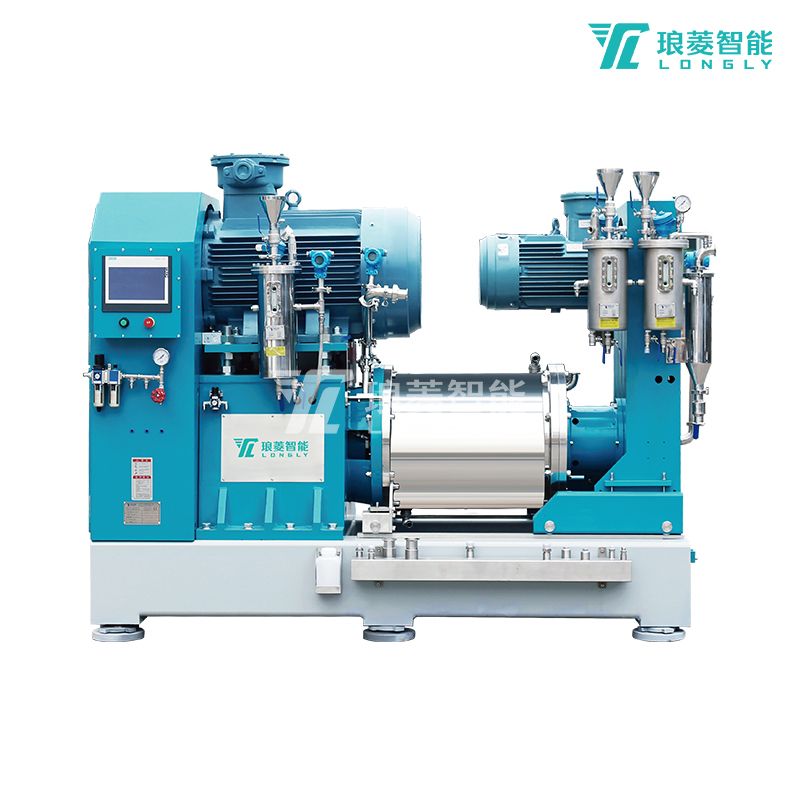

NT-V series of mass-produced rod-pin nano sand grinding machines

The high-efficiency pin nano bead mill independently developed by Longly won the "Dongguan First Batch of Manufacturing Single Champion Products".

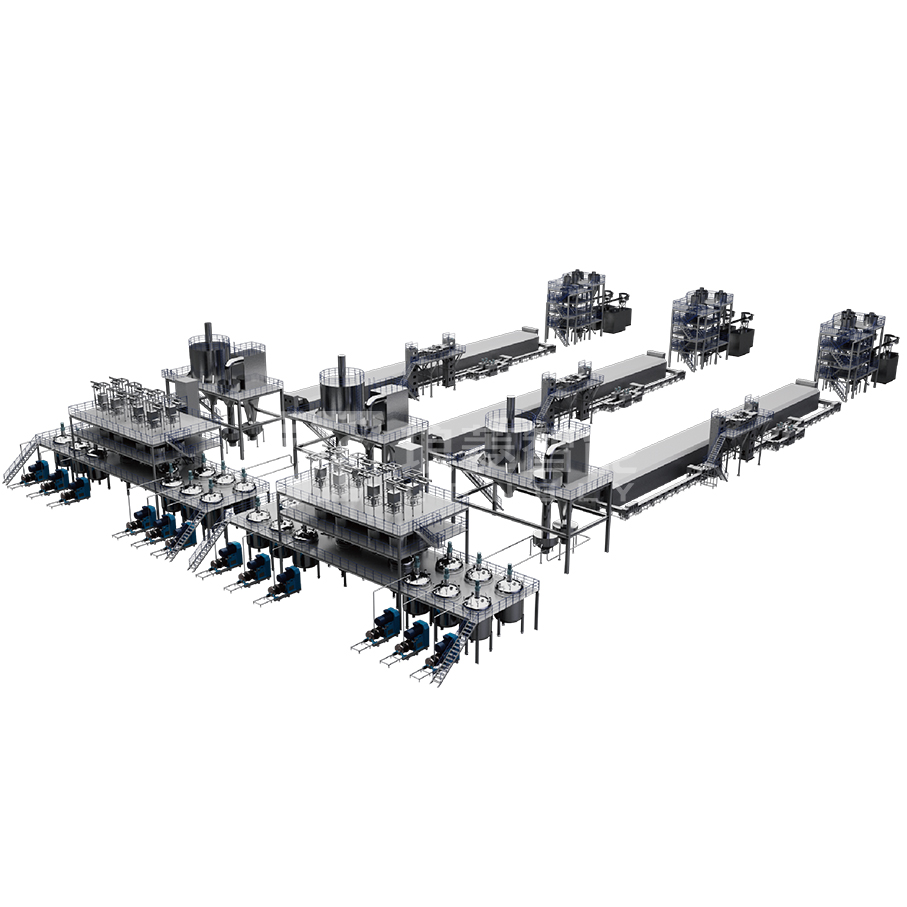

Rod and pin high efficiency grinding structure, suitable for nano level grinding large flow continuous, circulating production, production efficiency can be increased by 30-50% after production, widely used in nano new materials, magnetic materials, electronic ceramics, ceramic ink, lithium iron phosphate, alumina and other industries; Newly upgraded operating system, flow can be set on PLC, more accurate and stable; Added safety protection functions.

◎ Discharge particle size: 100nm-2um

Zirconium ball size: 0.2-2.0mm

◎ Viscosity: ≤30000cps

◎ Solvent system: water-based/oil-based

◎ Optional material: Tungsten carbide/polyurethane/zirconia/silicon carbide/silicon nitride

Technical advantages:

◎ High grinding effect, 1.3-1.5 times that of other equipment;

◎ Good grinding temperature control (equipment temperature is controlled at 38℃-45℃, without heat exchanger);

◎ Low unit energy consumption, unit energy consumption reduced by 21.7%;

Home

Home