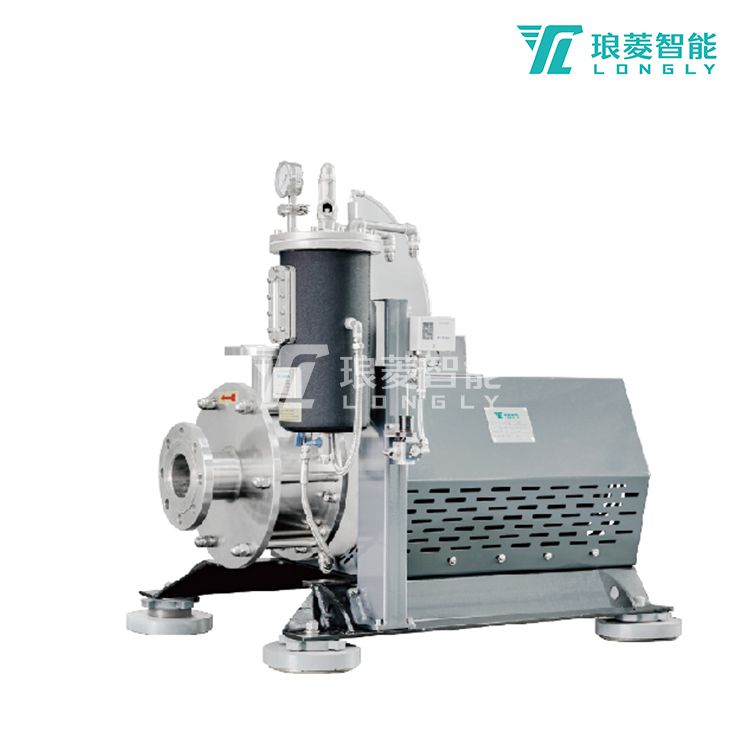

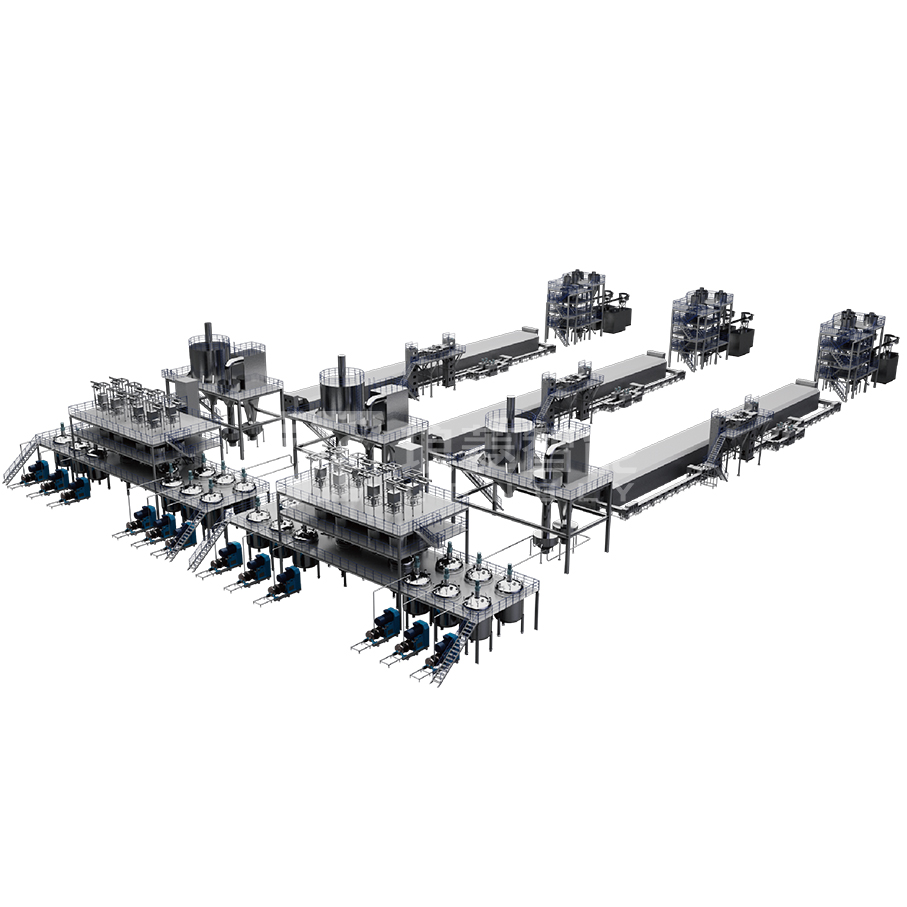

High pressure homogenizer

Mainly used for the mixing, homogenization, and nanomaterialization of solid-liquid solutions.

◎ Under the action of high pressure, liquid materials generate various forces (such as cavity effect, shear force, impact effect, etc.) through homogeneous components to interact with each other, causing a series of changes in physical and structural properties of the material, ultimately achieving the effect of homogenization and refinement.

◎ Users can adjust the working pressure and homogenization frequency of the high-pressure homogenizer according to their actual needs to achieve the desired homogenization effect.

Application industry:

Biology, medicine, food, chemical engineering, cell fragmentation, beverage homogenization, fine chemical engineering, preparation of liposomes, fat emulsions, nano suspensions, microemulsions, lipid microspheres, emulsions, dairy products, infusion solutions, dyes, solar panel coatings, and conductive coatings.

Home

Home