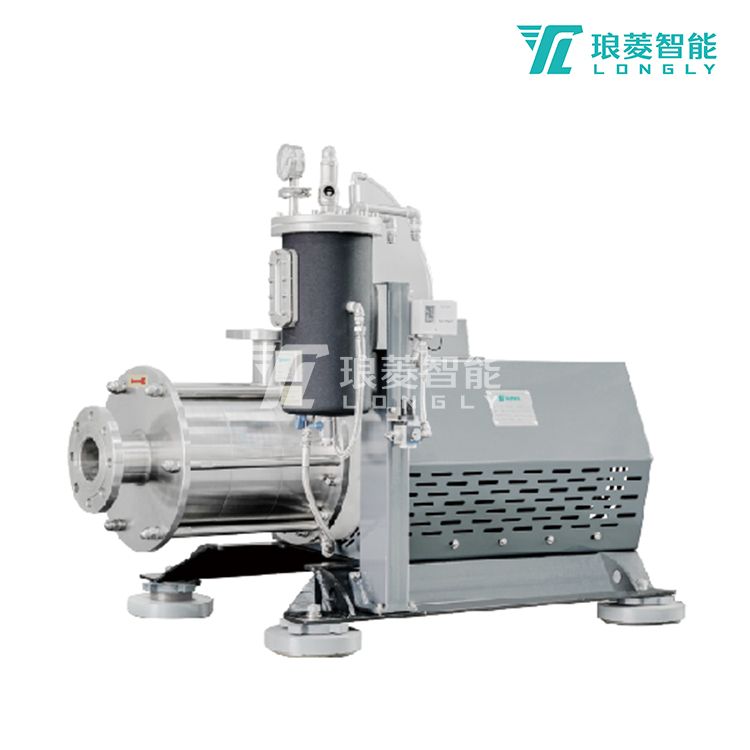

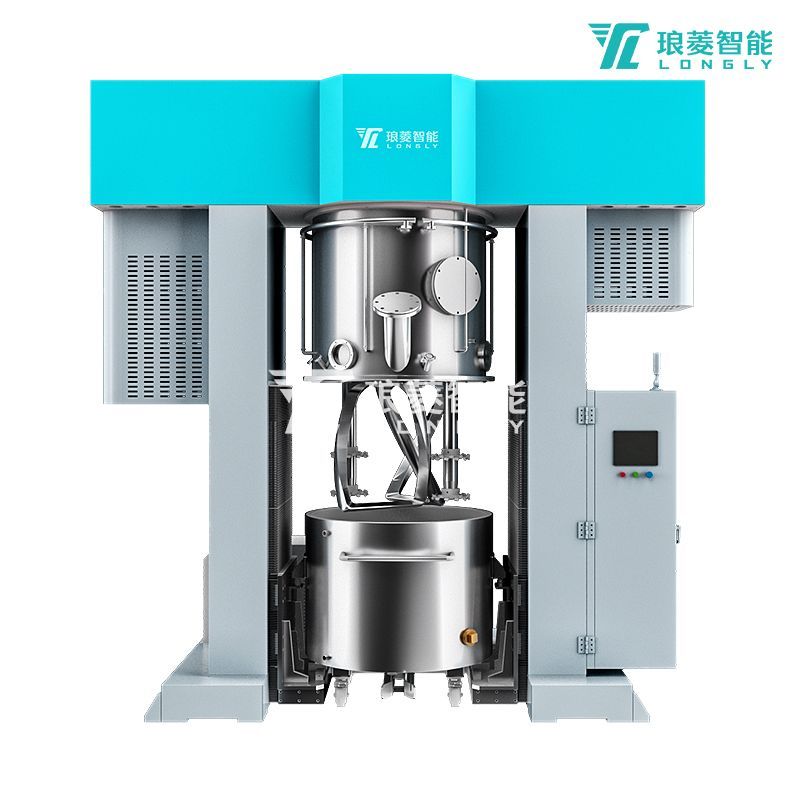

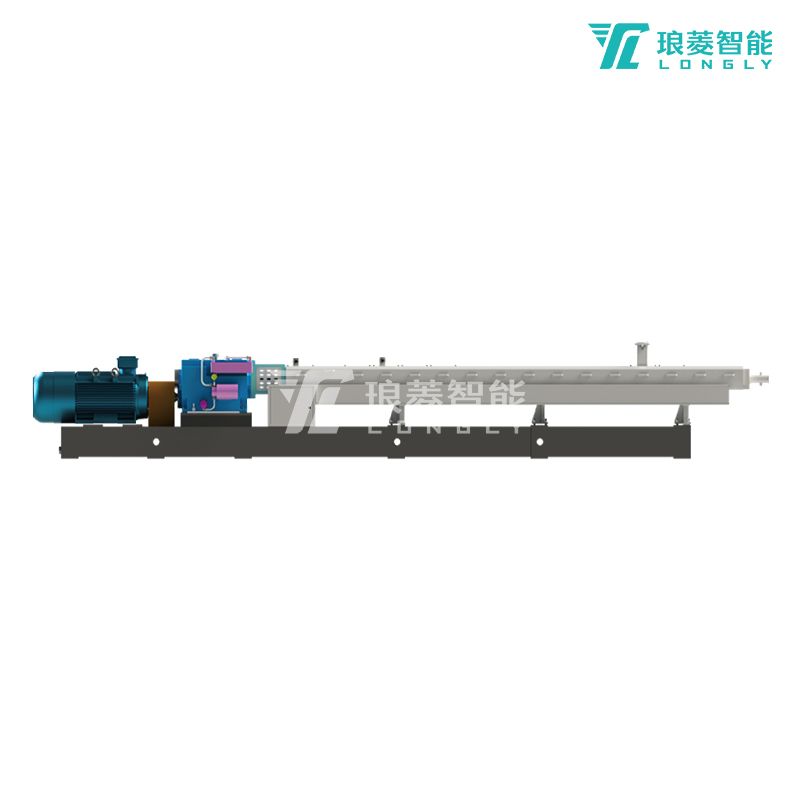

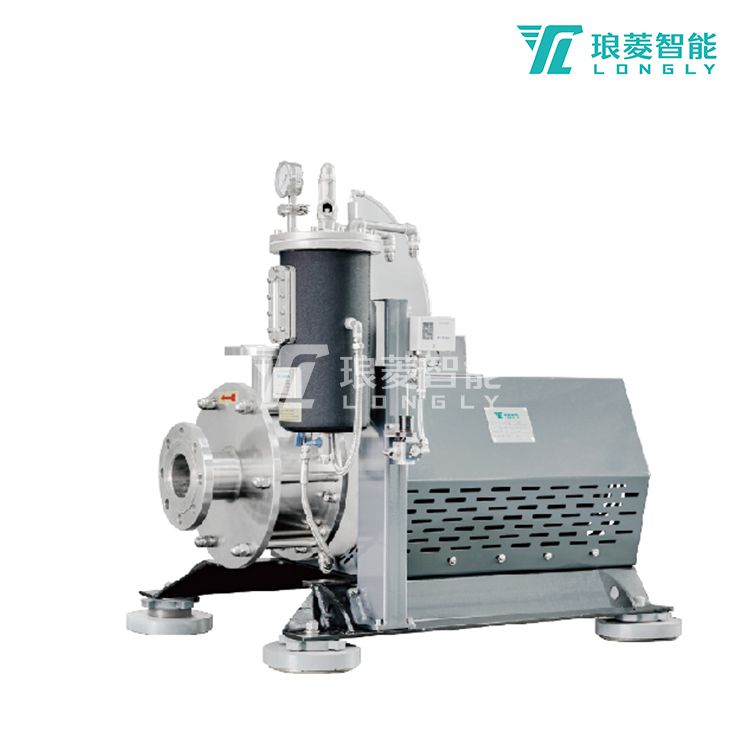

Triple level horizontal emulsification machine TRL3 series

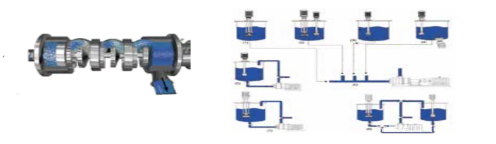

Dynamic principle, precise coordination between rotor and stator, optimized combination to achieve the best state of the system. The working head (rotor and stator forging manufacturing) has a claw structure, bidirectional suction, and high shear efficiency; It is achieved through the high-speed and smooth rotation of the rotor, resulting in a high frequency, strong circumferential tangential velocity, angular velocity, and other comprehensive kinetic energy efficiency; Under the action of the stator, a strong and reciprocating hydraulic shear, friction, centrifugal compression, liquid flow collision, and other comprehensive effects are formed in the reasonably narrow gap between the stator and rotor. The material circulates through the above working process in the container, ultimately obtaining the product.

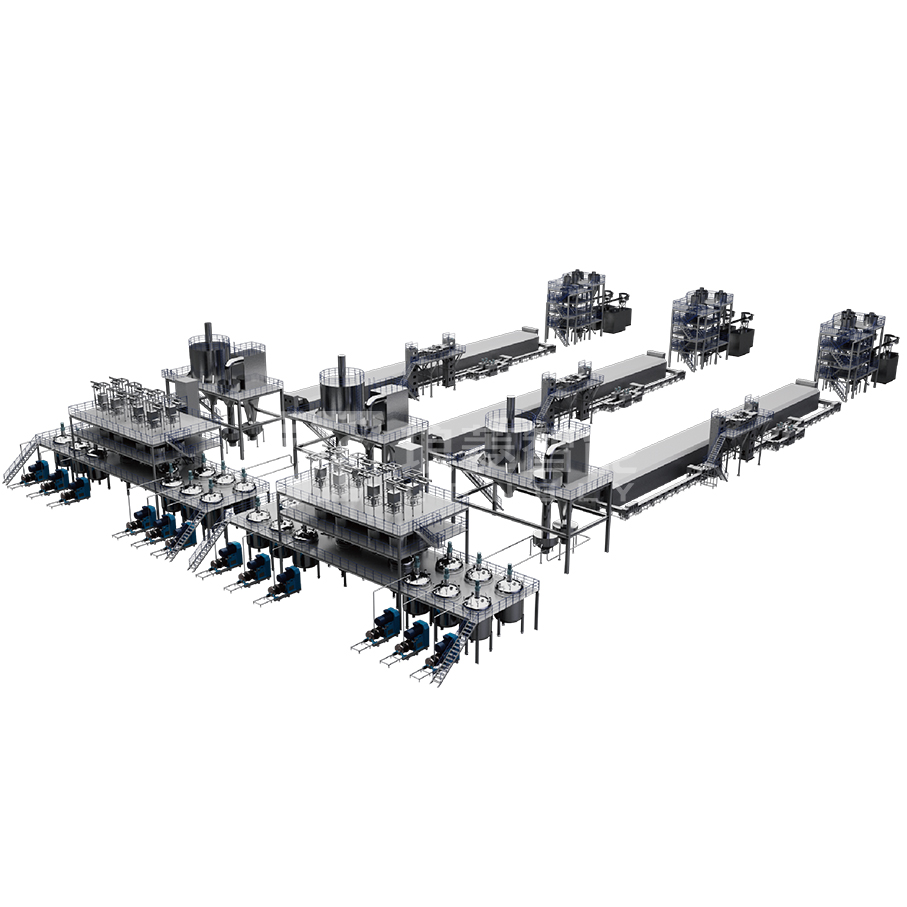

Application industry:

◎ Battery Electronics Industry ◎ Lithium Iron Phosphate ◎ Coatings ◎ Pharmaceuticals ◎ Pesticides

Home

Home