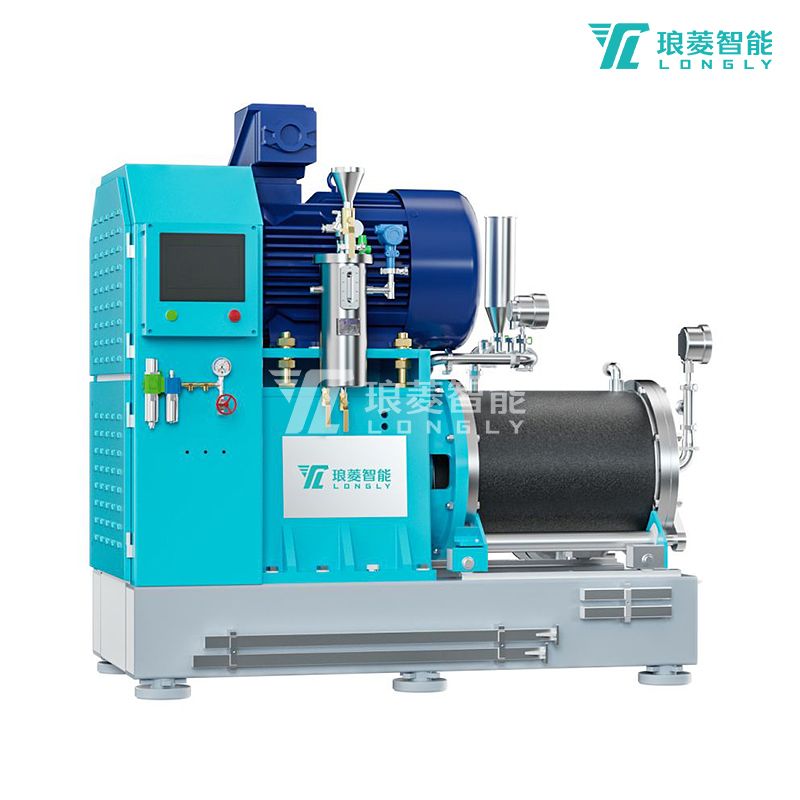

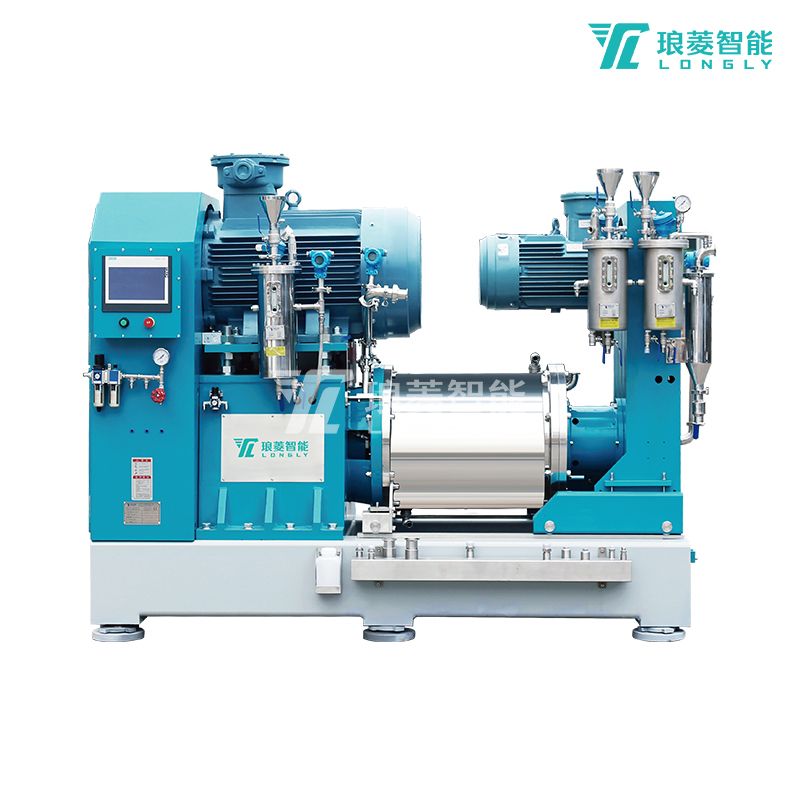

Turbine type nano sand grinder NT-X series

The conveying pump pumps the pre diluted and stirred liquid solid mixed raw materials into the cylinder, and the main shaft drives the dispersion turbine to rotate at high speed. It also agitates the grinding media (glass balls, ceramic balls, zirconia beads, alumina beads, etc.) in the cylinder, causing them to generate swirling and radial motion, thus grinding and dispersing the product to achieve the set fineness, At the same time, the working pressure and temperature are automatically controlled by an electric contact pressure gauge and an electric contact temperature gauge to ensure the safe operation of the entire machine. During this time, the product and grinding medium are separated by dynamic discharge gaps.

◎ Discharge particle size: 200nm-2um;

◎ Zirconium ball size: 0.3-2mm;

◎ Separation system: axial separation/large screen separation/ceramic plate separation;

◎ Grinding structure: turbine type;

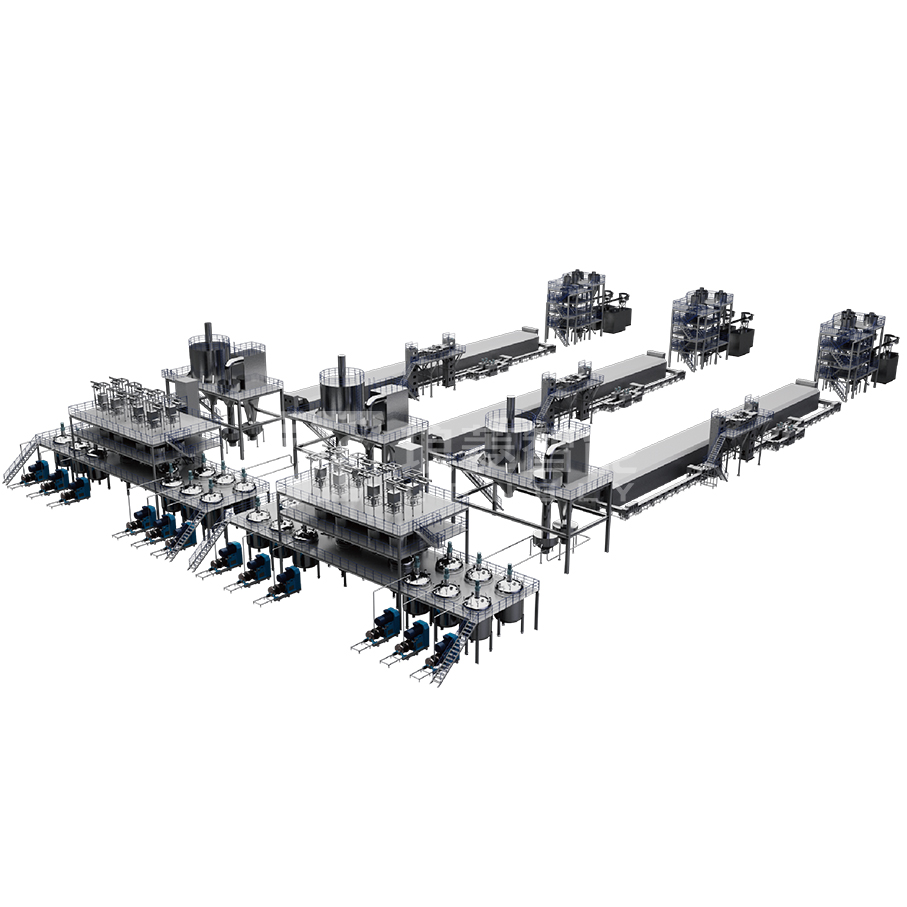

Application industry:

◎ Carbon nanotubes ◎ Nano ceramics ◎ Printing inkjet ◎ Barium titanate ◎ Aluminum oxide ◎ Barium carbonate ◎ Varistor ◎ Camera ink ◎ Zirconia

◎ Printing Ink ◎ Lithium Iron Phosphate ◎ PZT ◎ Catalyst ◎ LTCC&MLCC

Home

Home