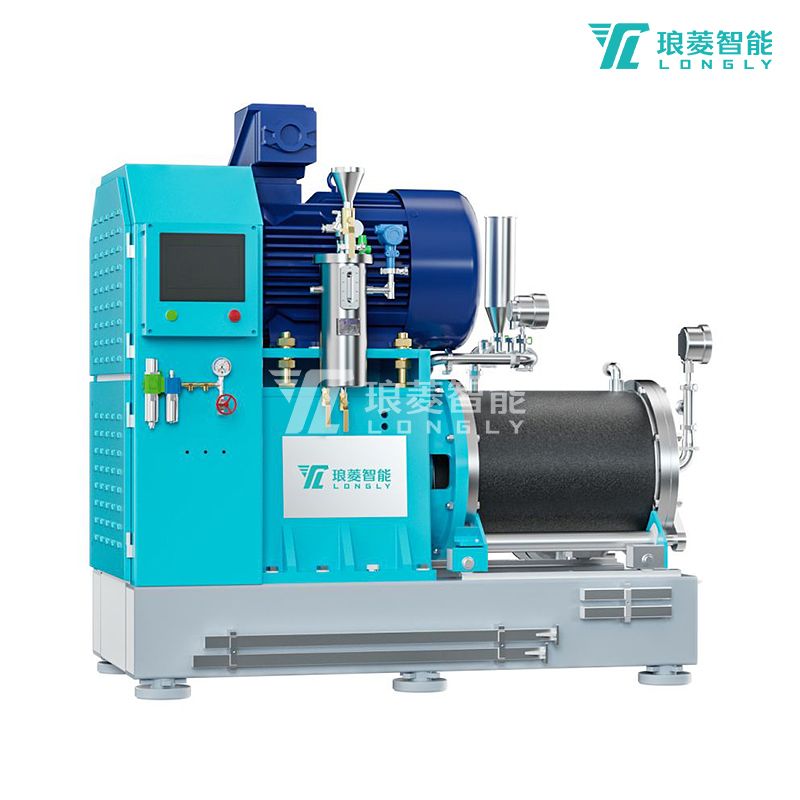

Dual power centrifugal nano sand grinder NT-S series

The dual-power centrifugal bead mill was selected: the first (set) key technical equipment project in Dongguan.

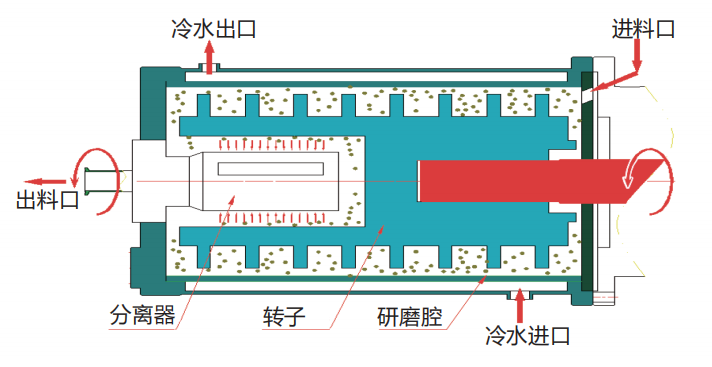

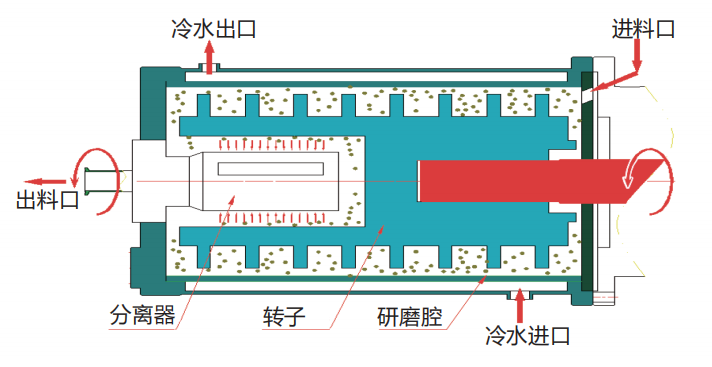

Dual power centrifugal nano sand grinder NT-S series Designed using the principle of (mesh free) centrifugal separation, the centrifugal separation has an independent power motor. During machine operation, most of the grinding zirconium balls are distributed around the periphery of the grinding chamber and move in the same direction as the object due to the centrifugal force of the disperser; A small amount of zirconium balls and materials rotate around the separator. The separator generates centrifugal force on the zirconium balls at high speed, which is greater than the pressure generated by the pump on the zirconium balls in the chamber. The zirconium balls stay in the grinding chamber, while the separator generates centrifugal force on the materials at high speed, which is less than the pressure generated by the pump on the chamber materials, forcing the materials to flow out of the separator. The grinding cylinder adopts silicon carbide material with good wear resistance and thermal conductivity, thus having a stronger application range.

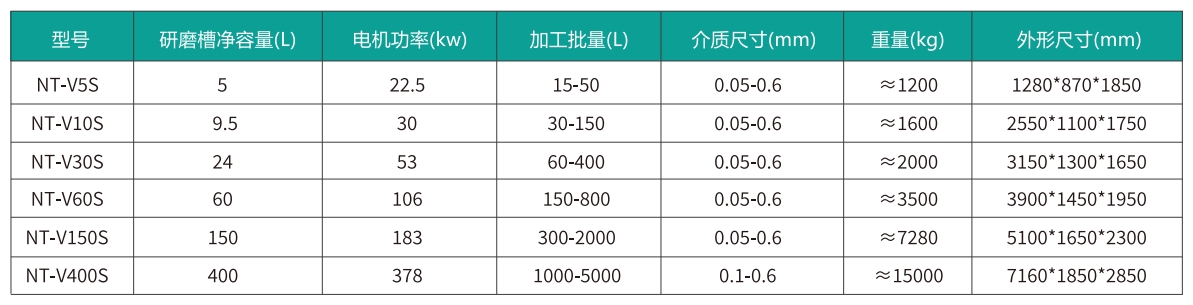

◎ Grinding particle size: 50-150nm

◎ Zirconium ball size: 0.05-0.6mm

◎ Separation system: centrifugal separation

◎ Grinding structure: rod pin type

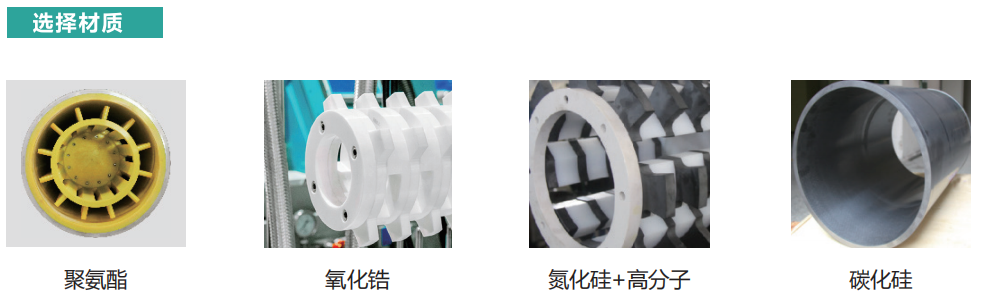

◎ Optional material: Tungsten carbide/polyurethane/zirconia/silicon carbide/silicon nitride

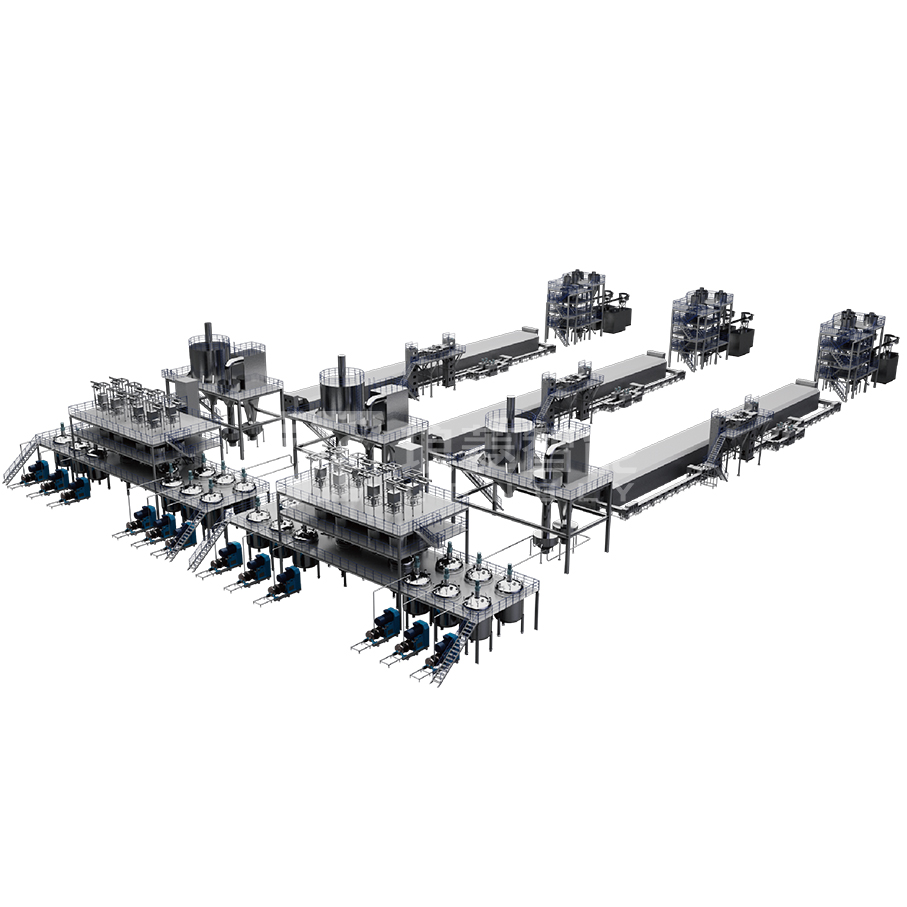

Ultrafine nano-level rod pin type efficient grinding machine, grinding fineness up to 100nm, material grinding and material separation independent operation, grinding more fine and thorough, unit time effective output is 2-3 times of the ordinary grinding machine, widely used in nano new materials, MLCC, lithium electricity, silicon carbon anode, alumina, ceramic ink and other industries.

Home

Home