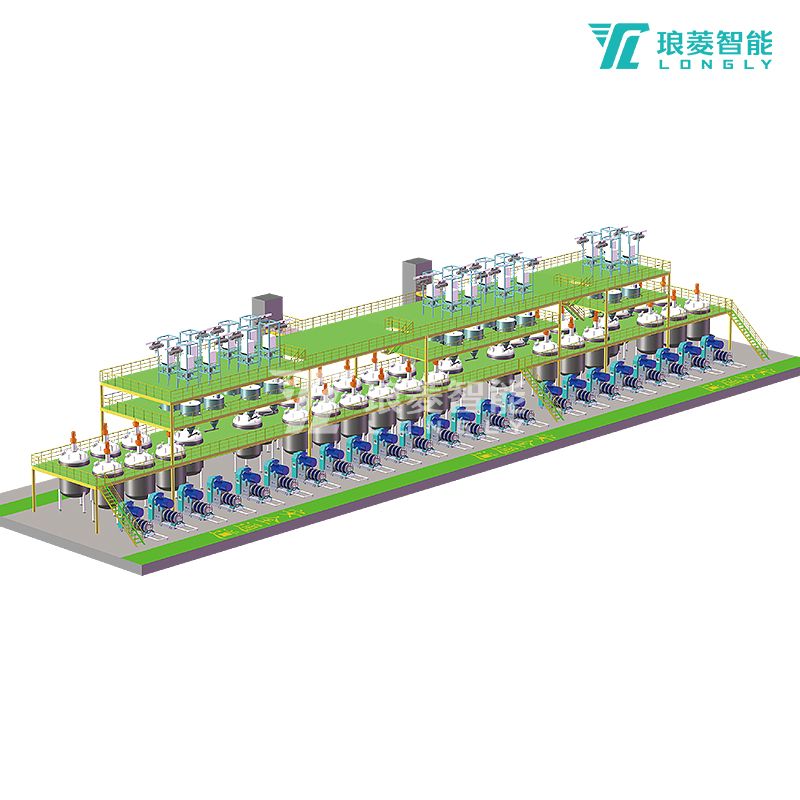

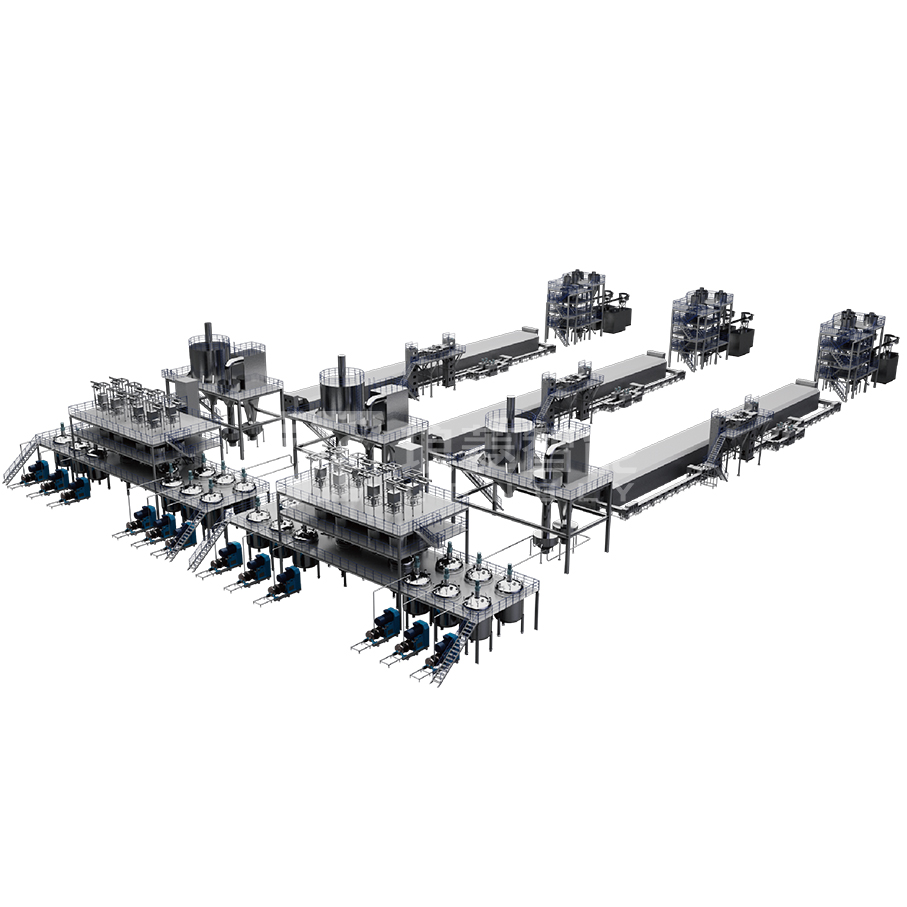

One stop service for powder material preparation

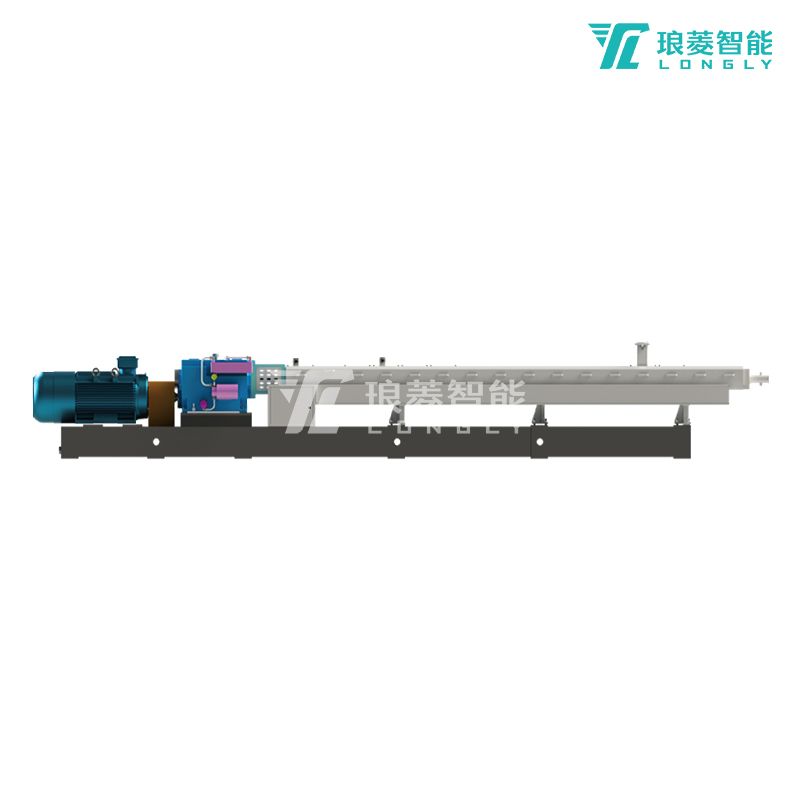

The entire process is fully enclosed, automated, digitized, and intelligent, which can meet the requirements of precise ingredients, stable quality, and intelligent control. Automation equipment and control programs connect various processes in a reasonable, orderly, and coordinated manner, maximizing product quality and production capacity. The equipment and components used, as well as the exposed parts that come into contact with materials, are prohibited from bringing in foreign matter pollution sources.

Product functional features:

◎ The entire production system can be completed through computer automatic or manual programs, and its better error prevention and correction ability effectively improves the batch stability of products;

◎ Strong traceability of product quality, real-time retrieval of formulas and production data, analysis of production data, providing a basis for optimizing processes and increasing production capacity;

◎ Real time monitoring of the outlet pressure sensor of the equipment delivery pump, equipped with low and high pressure alarms to prevent system explosion and pump evacuation;

◎ One click start for system operation: Once the parameters are set, the process system will automatically complete. Real time storage of operating parameters during the operation process, access and query at any time, and authorization to start/stop;

◎ Equipped with remote viewing function, users can log in to the factory system through their mobile phones or computers to view the production and equipment operation status. Control system hierarchical authorization to avoid unauthorized operations.

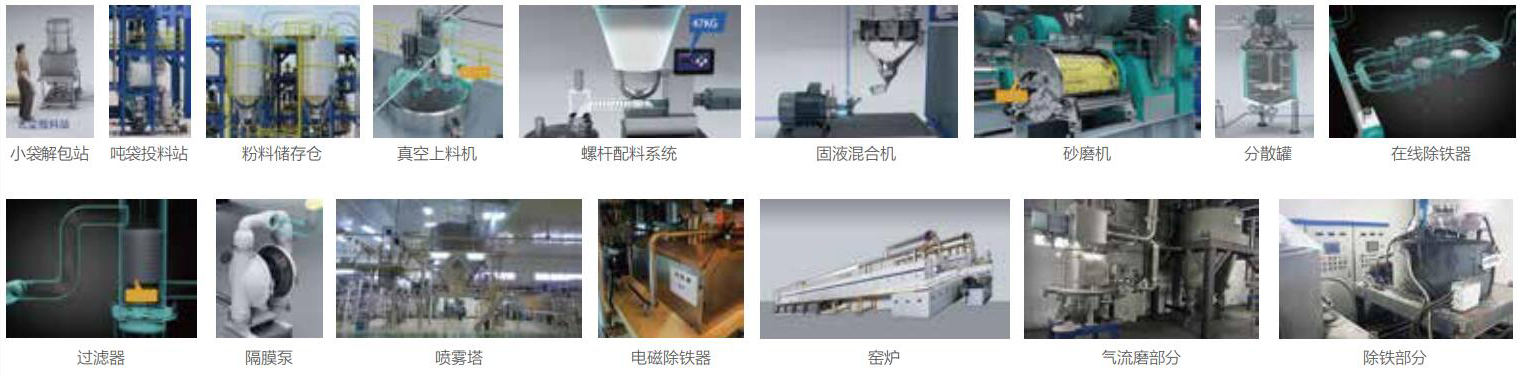

Application field:

Lithium iron phosphate, lithium acid, ternary, lithium manganese iron phosphate

Home

Home