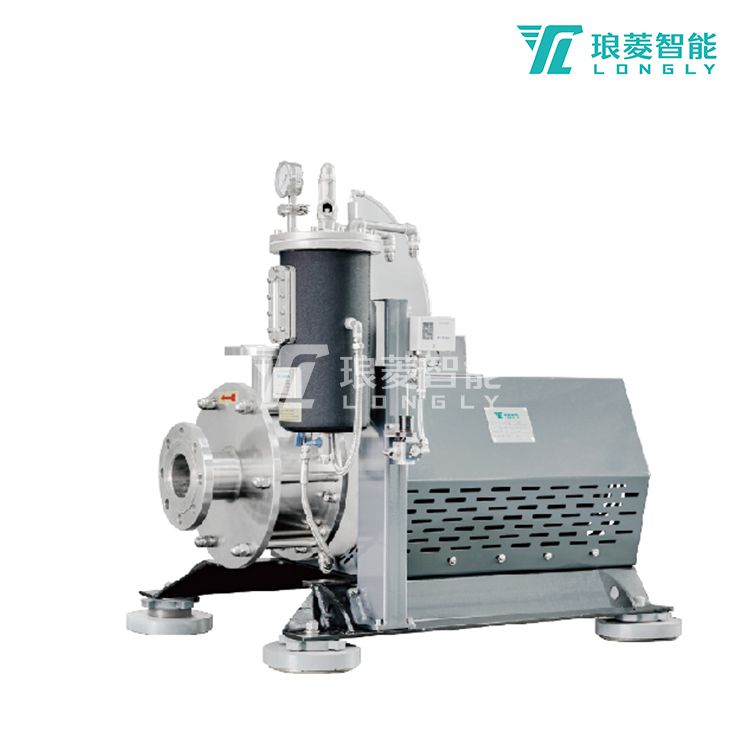

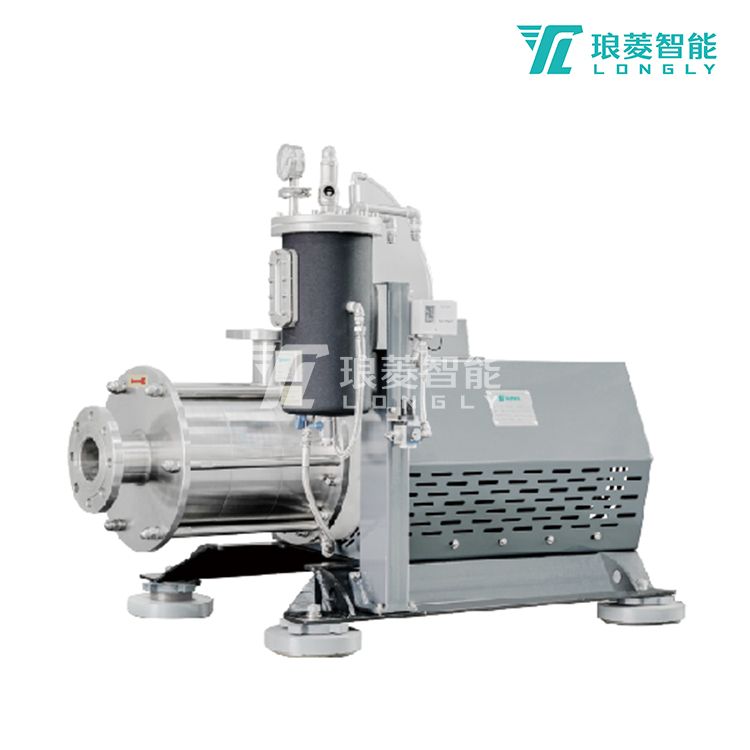

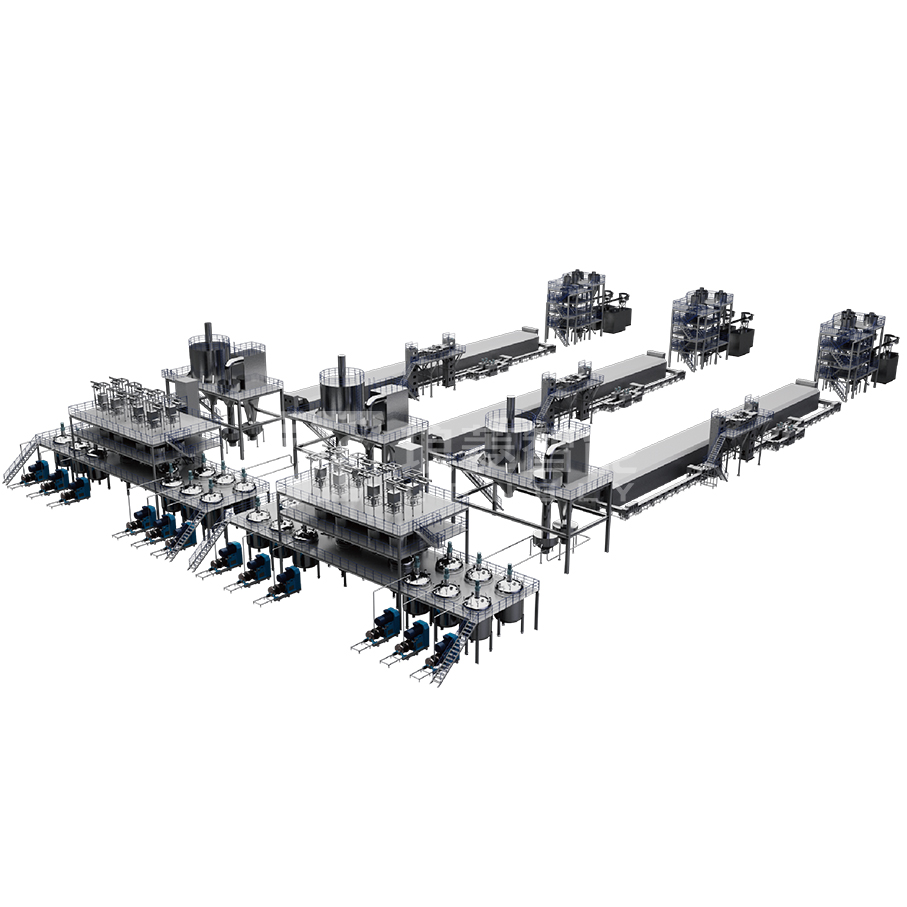

Nano ultrasonic high-speed dispersion machine GF series

After entering the dispersion chamber, the slurry quickly detaches from the dispersion wheel under the high-speed rotation of the dispersion wheel, passes through the dispersion holes, and after strong impact on the outer barrel wall, it returns to the inside of the dispersion wheel for the next cycle. In the process of repeated circulation, the large particles of agglomerates in the slurry are rapidly dispersed under the combined effects of laminar flow, turbulence, and cavity effects, which can effectively break down the agglomerates, achieve very uniform material dispersion, and ensure that the internal structure of the slurry is not damaged.

Application industry:

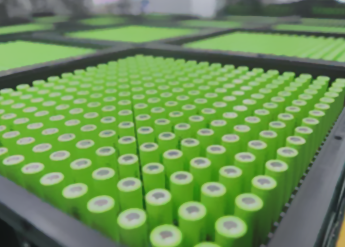

◎ Lithium Battery Materials ◎ Diaphragm ◎ Electronic Ceramics ◎ Nano Materials ◎ 5G Materials

Home

Home