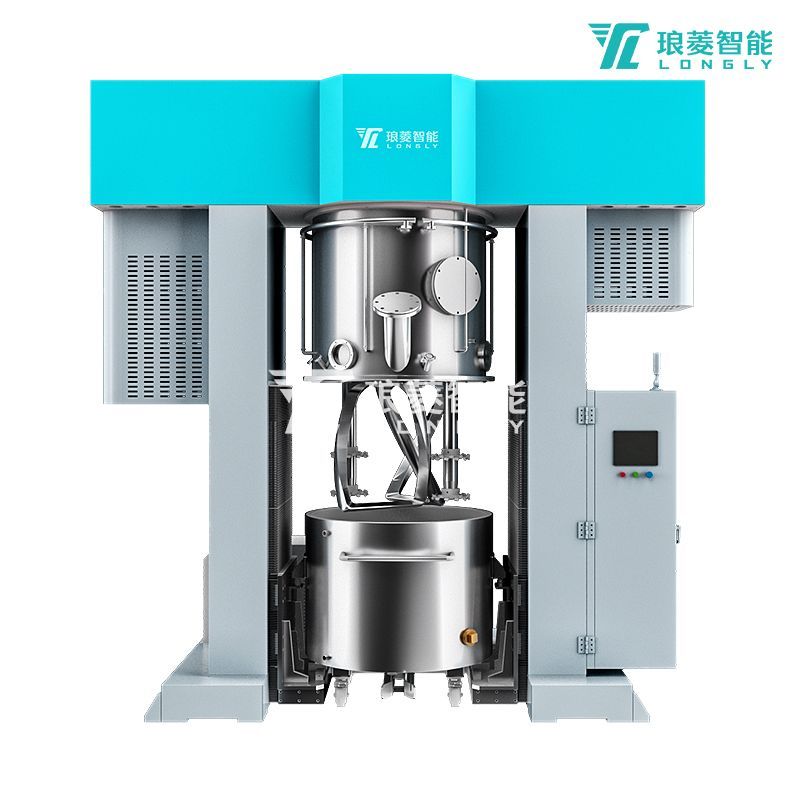

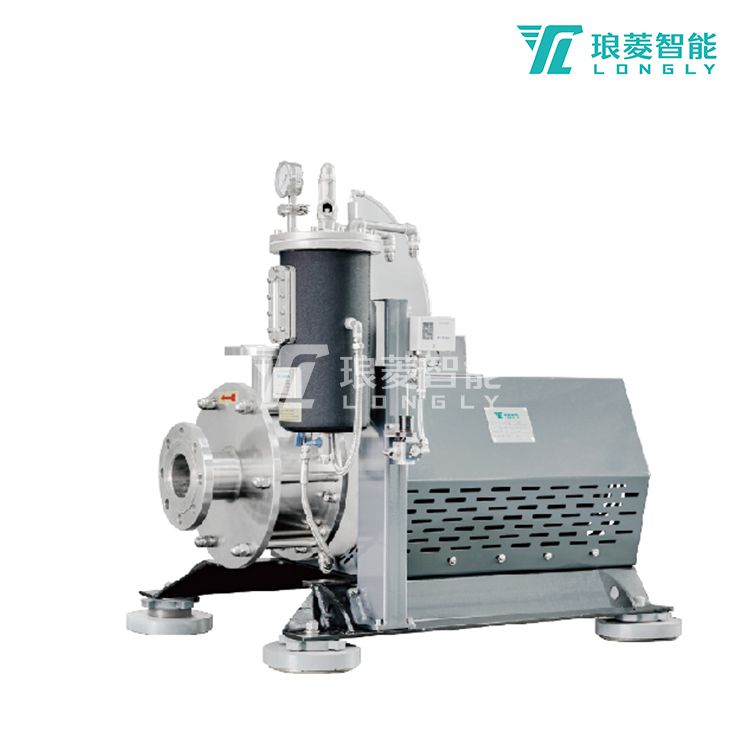

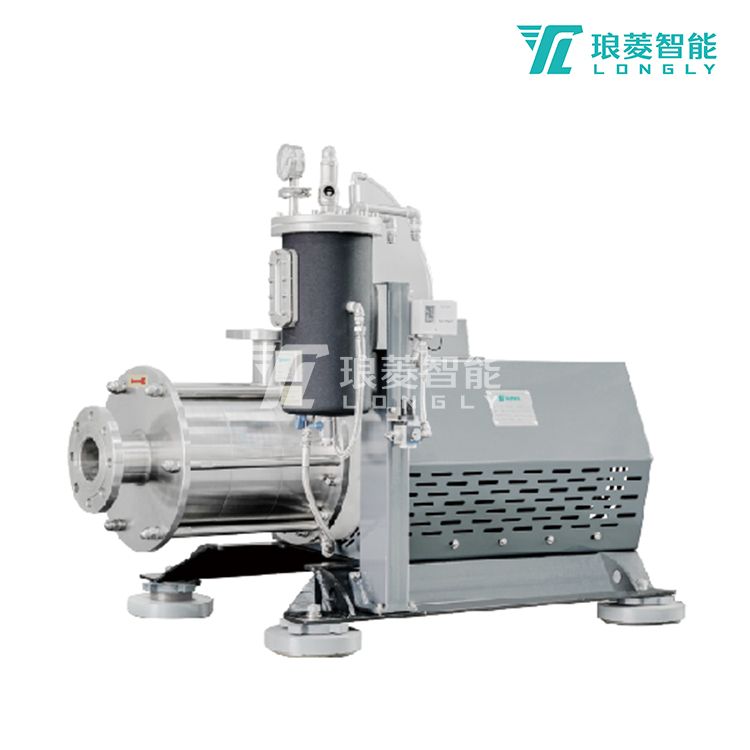

Vertical mixing and emulsification machine LRH series

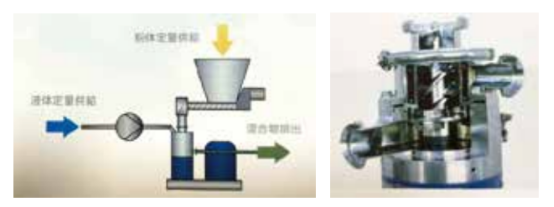

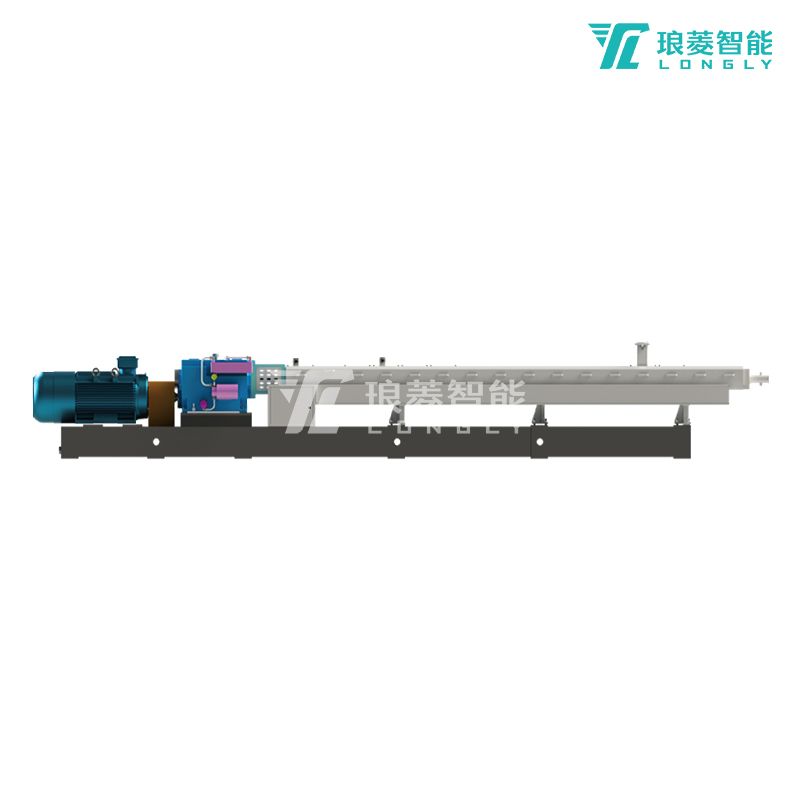

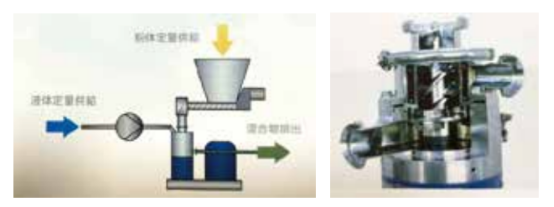

◎ A displacement pump can be used to feed the liquid phase from the inlet of a pressurized feeding system. The liquid is injected into the coaxial drum of the LY vertical mixing and emulsification machine and enters the pre mixing chamber through multiple holes;

◎ Use a batching device to vertically feed solids into the pre mixing chamber from the top through a chute. The dry material area and wet material pre mixing chamber are separated by feeding screws;

◎ The liquid and solid phases are mixed in a predetermined ratio in the pre mixing chamber. And immediately upon leaving the pre mixing chamber, it is subjected to a rotor with high shear force;

◎ The mixed product is discharged from the low liquid outlet in the device under the action of gravity and centrifugal force. This unique wetting method reduces the trapped air generated in solid/liquid dispersion systems.

Core mixing device:

The patented internal kneading planetary propeller adopts the 3D printing melt casting integrated molding process, and through CNC multi axis linkage composite processing (turning grinding finishing), the more optimized section shape has lower resistance and lower energy consumption, which is 4-5 times the efficiency of the ordinary propeller (compared with the ordinary pentagon Fried Dough Twists propeller).

◎ During the movement of the paddle, there is a kneading, squeezing, and granulation effect between the entire outer surface and the gap between the inner liner of the bucket;

◎ The contact area of the fan-shaped curved surface is larger than the sharp angle, and there is a front and rear diversion area, which has a high frequency of contact with the material.

Attachment: The flow rate is set by adjusting the dosage. The required energy and degree of mixing depend on the selected speed and tool configuration. For simple processes, a volumetric dosage system is sufficient. For fully continuous processes with high requirements, precise metering and dosing pumps are used for liquids, and differential weighing is used for solids, which can be accurate to within 0.5% or less.

Application industry:

◎ Battery Electronics Industry ◎ Lithium Iron Phosphate ◎ Coatings ◎ Pharmaceuticals ◎ Pesticides

Home

Home