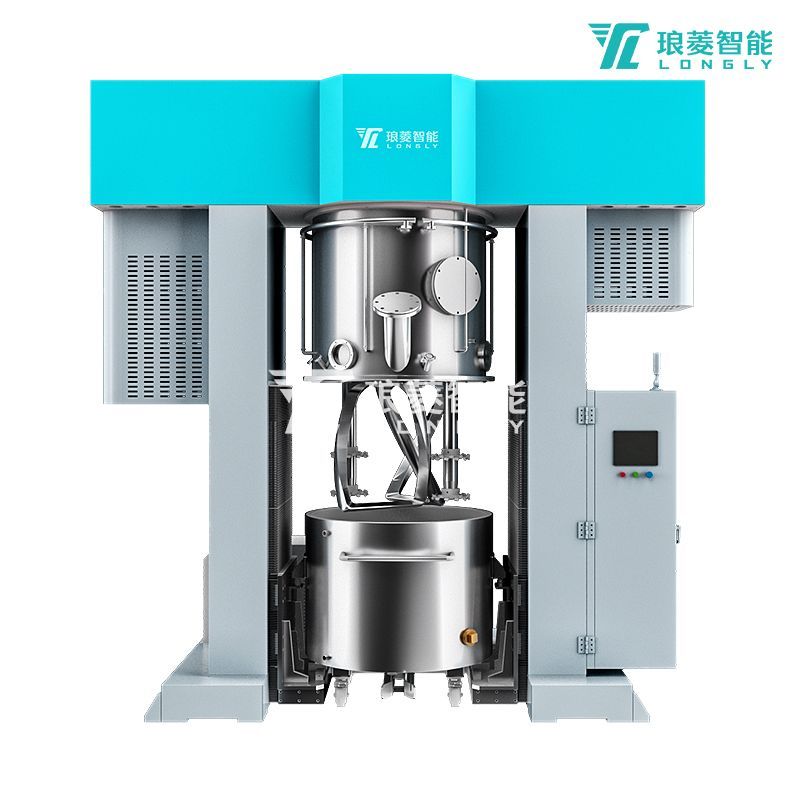

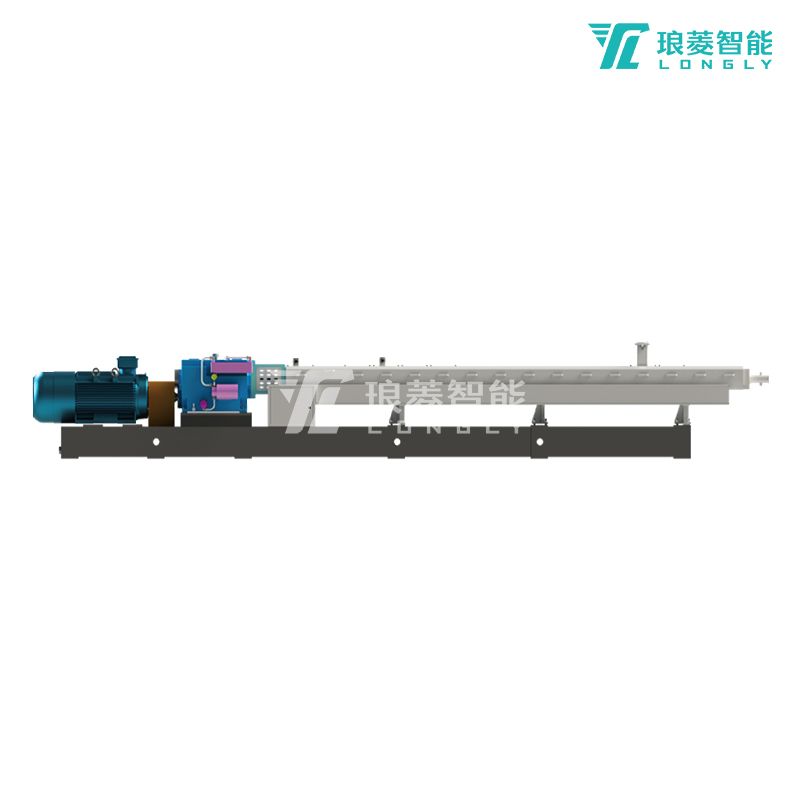

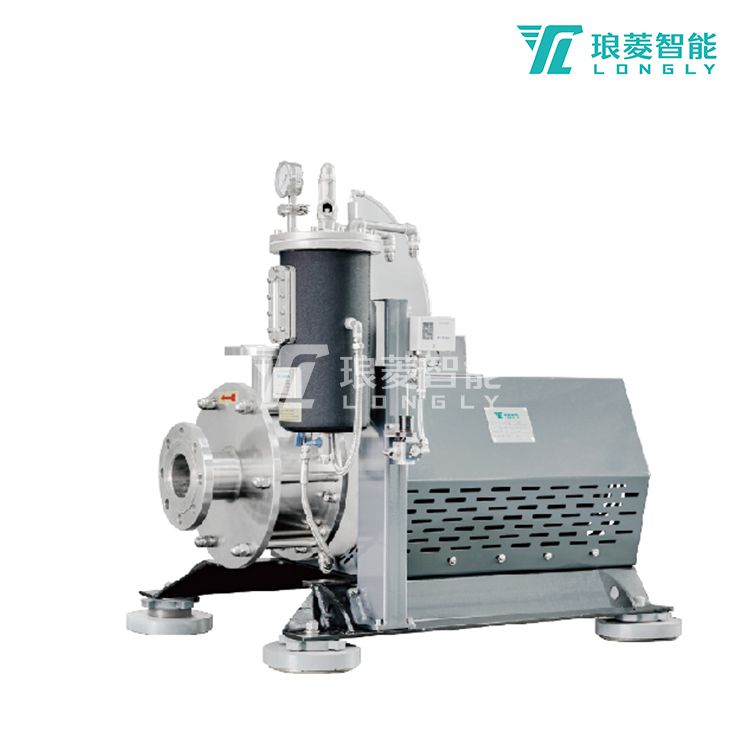

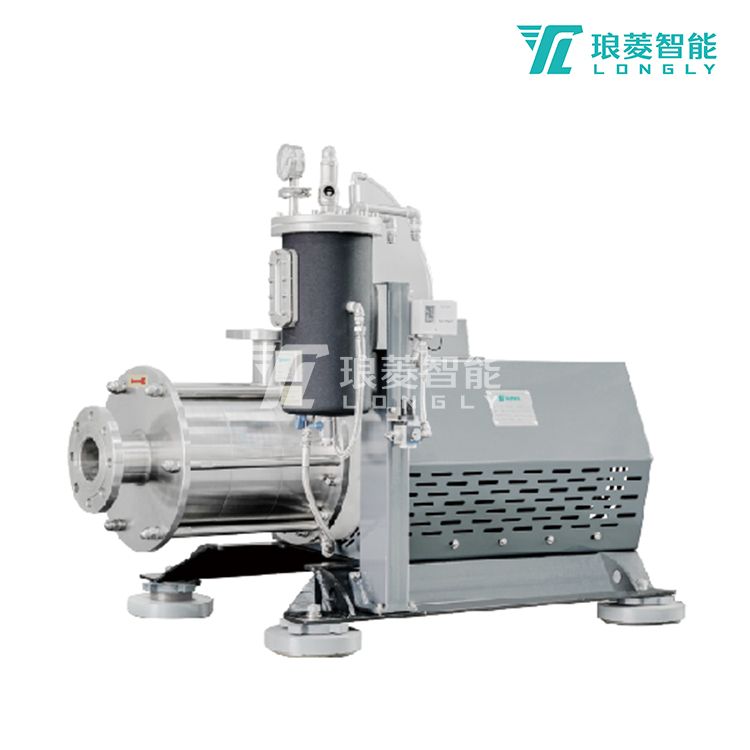

During the operation of the MT/LMT series power vacuum mixer, two parallel mixing paddles operate according to a set fixed rotation ratio, rotating rapidly along the mixing barrel, allowing the material to move from the inner wall of the mixing barrel to the vicinity of the mixing paddles. The other two separate power units' high-speed dispersion gear discs also operate along the mixing drum with the revolution for efficient dispersion and emulsification. The mixing paddle and high-speed dispersion gear discs are both variable frequency speed regulation, which can be customized according to the production process to achieve different shear purposes. This type of movement can achieve a completely uniform mixing effect of materials in a short period of time.

Core mixing device:

The patented internal kneading planetary propeller adopts the 3D printing melt casting integrated molding process, and through CNC multi axis linkage composite processing (turning grinding finishing), the more optimized section shape has lower resistance and lower energy consumption, which is 4-5 times the efficiency of the ordinary propeller (compared with the ordinary pentagon Fried Dough Twists propeller).

◎ During the movement of the oar, there is a kneading, squeezing, and granulation effect between the entire outer surface and the gap between the inner container of the bucket;

◎ The contact area of the fan-shaped curved surface is larger than the sharp angle, and there are front and rear flow guide areas, which have a high frequency of contact with materials.

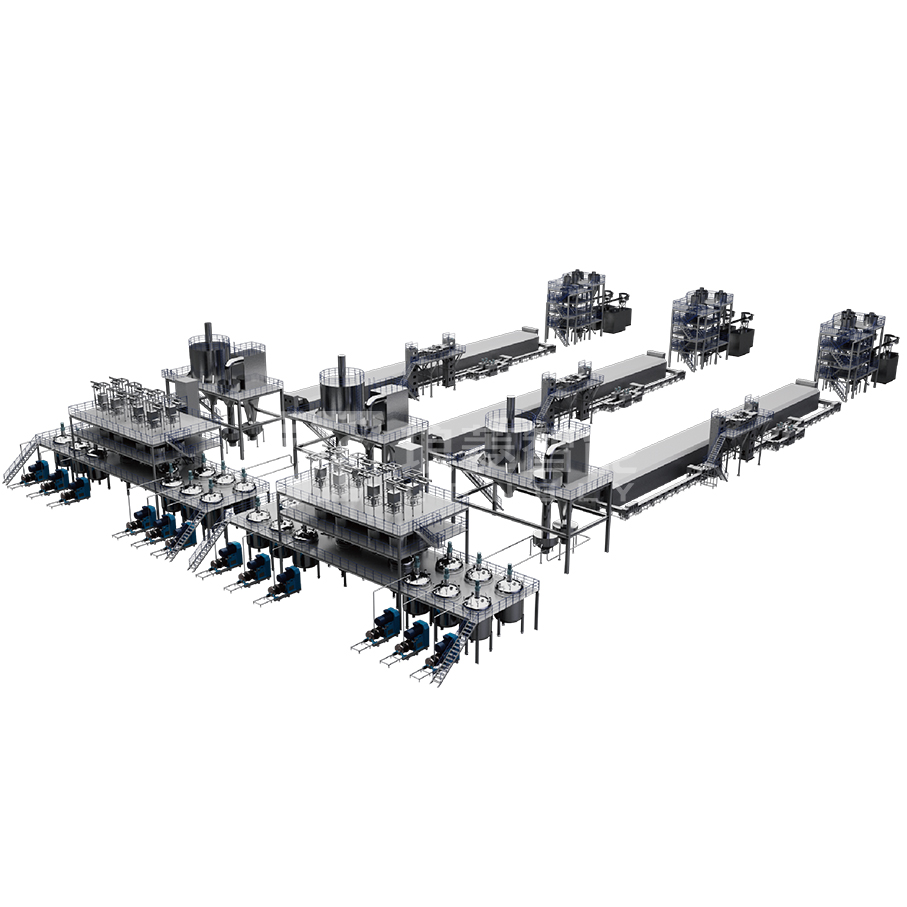

Application industry:

◎ Polymer lithium-ion battery fluid ◎ Liquid lithium-ion battery fluid ◎ Electronic electrode slurry ◎ Polyurethane sealant ◎ Silicone sealant ◎ Adhesive

◎ Mold adhesive ◎ Anaerobic adhesive ◎ Cosmetics ◎ Ink ◎ Pigments ◎ ointments ◎ Electronics ◎ Chemicals ◎ Food ◎ Pharmacy ◎ Building materials ◎ Pesticides

Home

Home